用于货运卡车车身的高性能闭孔硬质 PET 泡沫可减轻重量,同时增强抗冲击性,延长使用寿命,并使材料可回收利用。

描述

Freight truck body panels incorporate high-performance closed-cell rigid PET foam as the core material, which enhances impact resistance and extends service life while reducing body weight. This material is also recyclable, aligning with the concept of green and sustainable development.

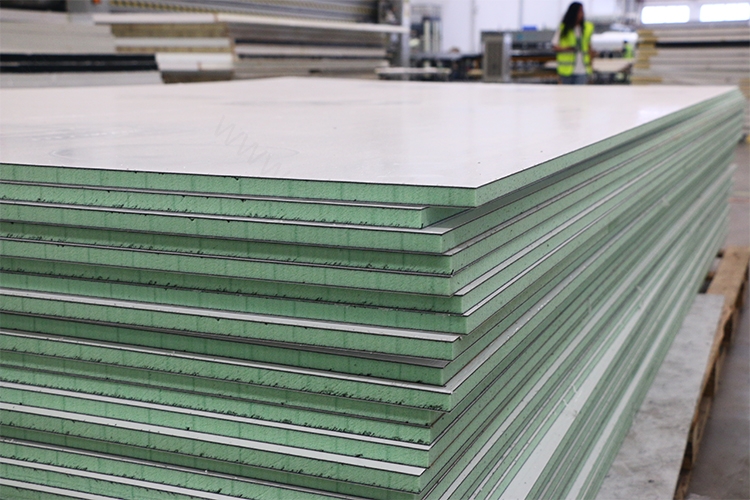

规格

- Core: PET foam board

- Skin: Fiberglass, aluminum, pre-painted steel, stainless steel, etc

- Width: ≤3.2m

- Length: ≤12m

- Thickness: 10~120mm

- Core Density: 50~300 kg/m³

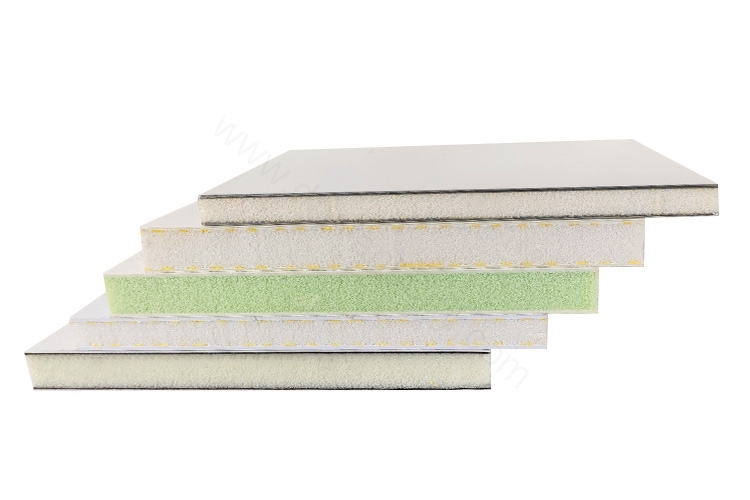

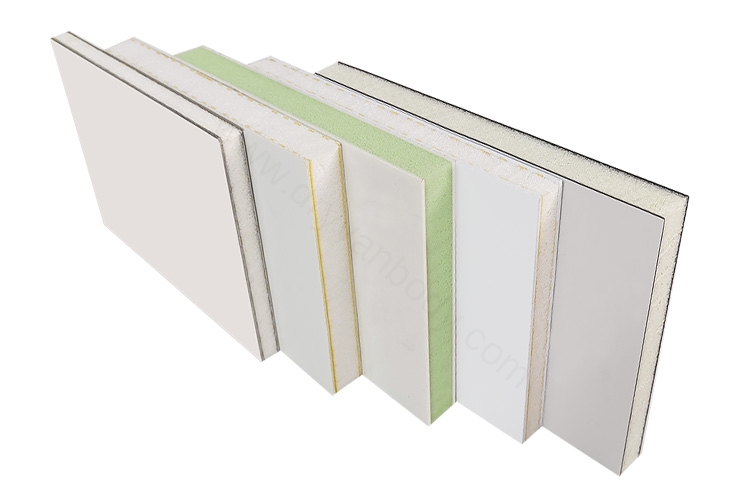

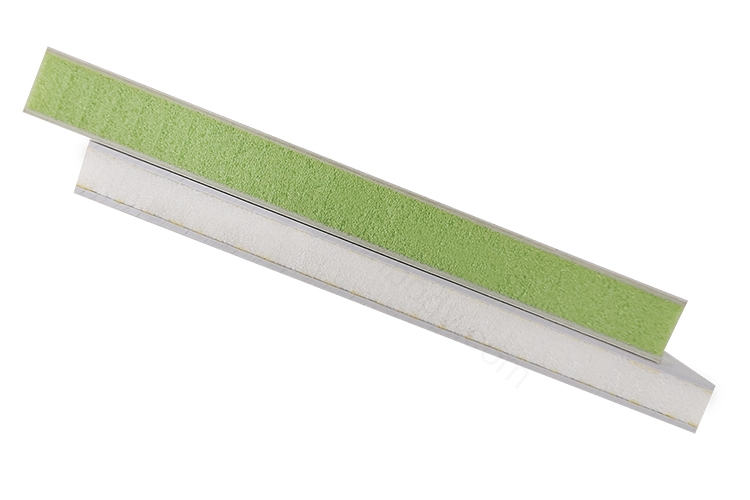

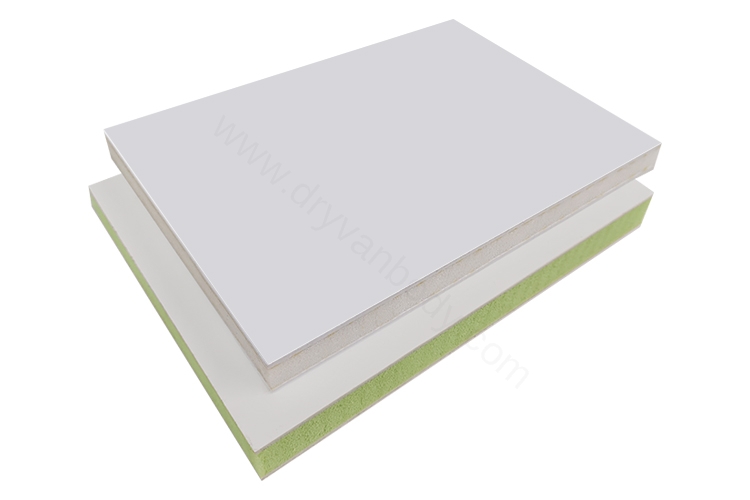

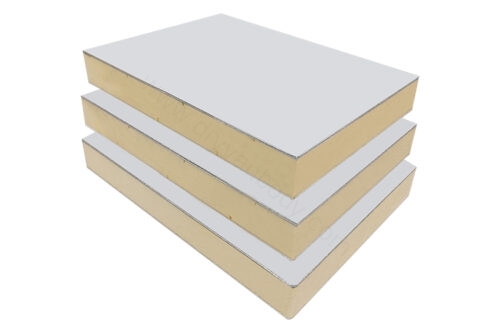

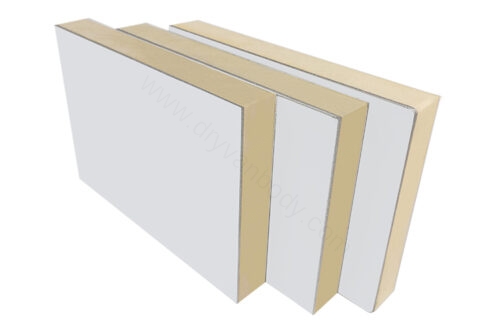

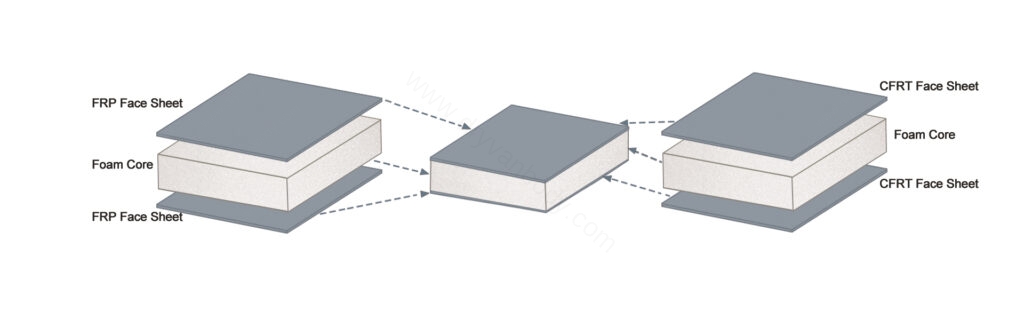

卡车车身面板的结构

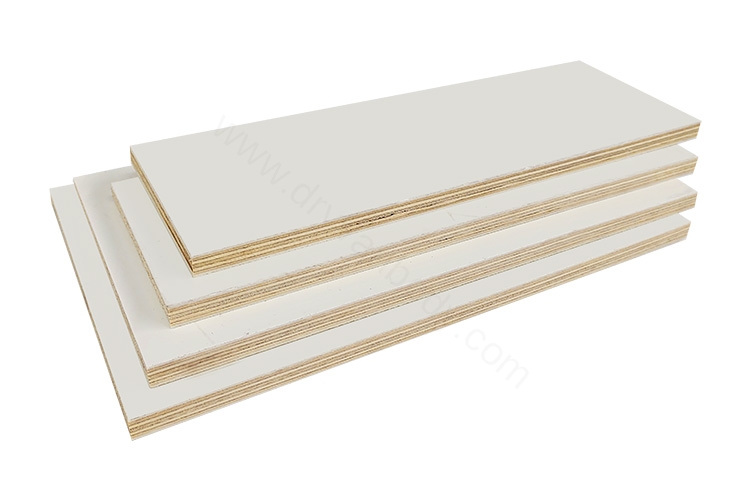

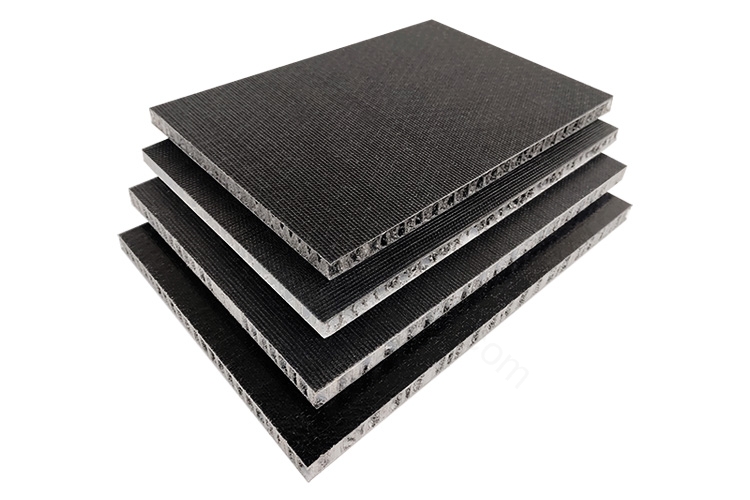

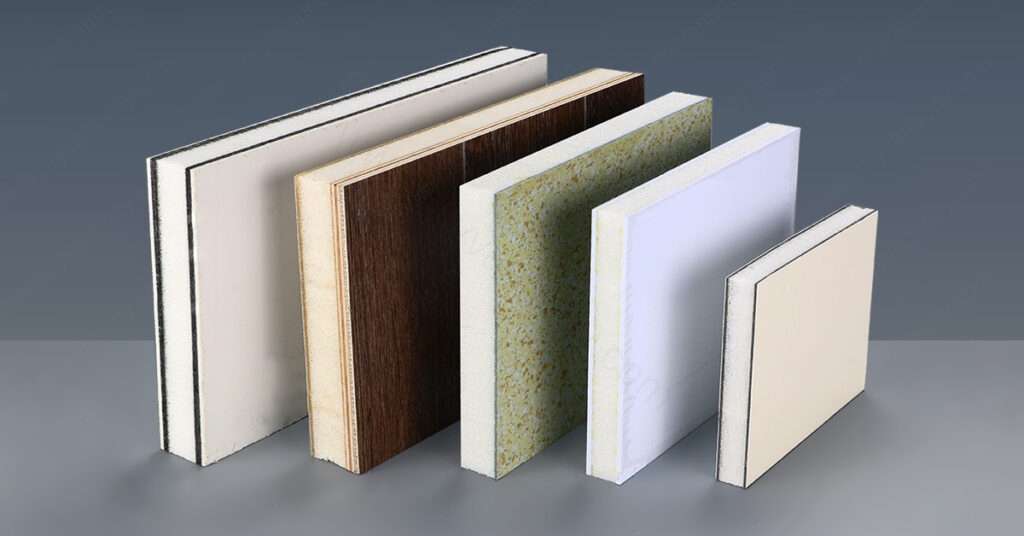

PET foam cores offer broad compatibility and efficiently laminate with various skin materials, including FRP, aluminum, stainless steel, color-coated steel, and plywood.

卡车车身玻璃纤维 PET 泡沫板的特点

- 重量轻:玻璃钢 PET 泡沫板比传统材料更轻。

- 强度高:玻璃钢 PET 泡沫夹层板具有良好的抗压强度和抗冲击强度,可提供有效的人体保护。

- 隔热:玻璃钢 PET 泡沫复合板具有良好的隔热性能,有助于保持车内温度稳定。

- 防水:玻璃钢 PET 泡沫夹芯板具有良好的防水和防潮性能,适合在各种气候条件下使用。

- 耐化学性:PET 泡沫塑料对多种化学品和溶剂具有很强的耐受性。

- Easy to process: PET foam panels are easy to cut, shape, and install, with customization options available to meet specific requirements.

- Eco-friendly: PET foam can be recycled.

- Flat & Smooth surface: Low wind resistance, easy to clean, and convenient for the customizing body color, brand logo or advertising.

- Anti-scratch: The panel uses continuous glass fiber reinforced plastic as the surface layer, providing anti-scratch performance and extending the panel’s service life.

玻璃纤维 PET 泡沫夹芯板

CARBODY has successfully developed CFRT (Continuous Glass Fiber Reinforced Thermoplastic), a material that exhibits significantly higher toughness than traditional thermosetting FRP. It is extremely light, thin, and strong. This is an important technological innovation in the field of materials science.

应用

Fiberglass PET composite panels are lighter, stronger, more durable, and cheaper than traditional metal or wood. Widely used in RV and box truck manufacturing for wall panels, floors, partitions, and roof panels.