Freight truck body panels use high performance closed-cell rigid PET foam as the core material, which enhances impact resistance and prolongs service life while realizing lightweight body, and the material can be recycled, in line with the concept of green and sustainable development.

คำอธิบาย

Freight ตัวรถบรรทุก panels use high performance closed-cell rigid PET foam as the core material, which enhances impact resistance and prolongs service life while realizing lightweight body, and the material can be recycled, in line with the concept of green and sustainable development.

ข้อมูลจำเพาะ

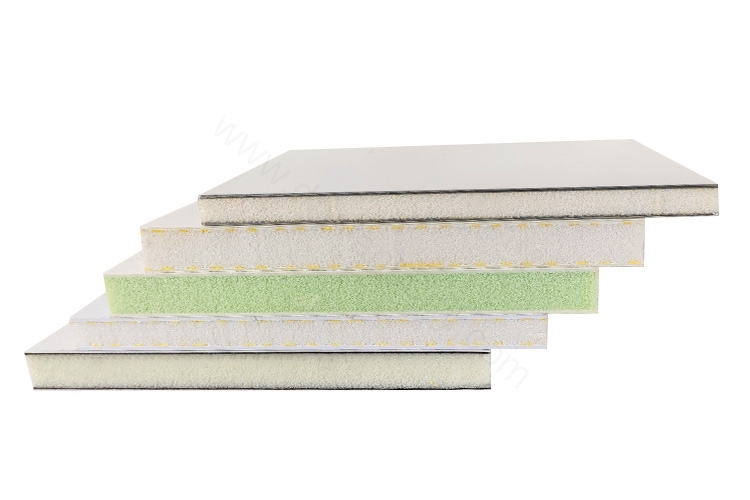

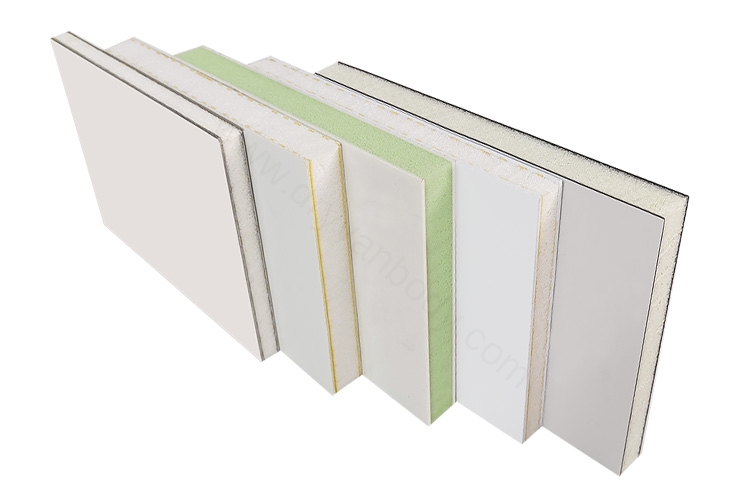

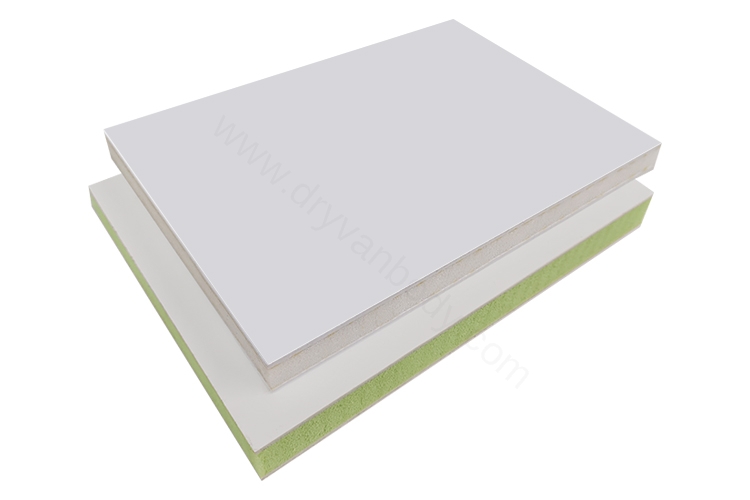

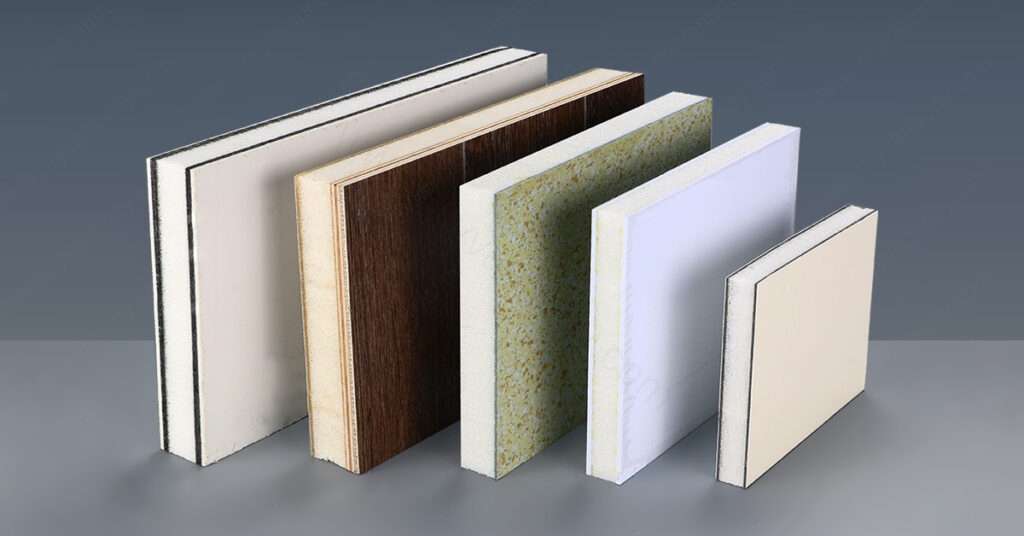

- Core: PET foam board

- Skin: Fiberglass, aluminum, pre-painted steel, stainless steel, etc

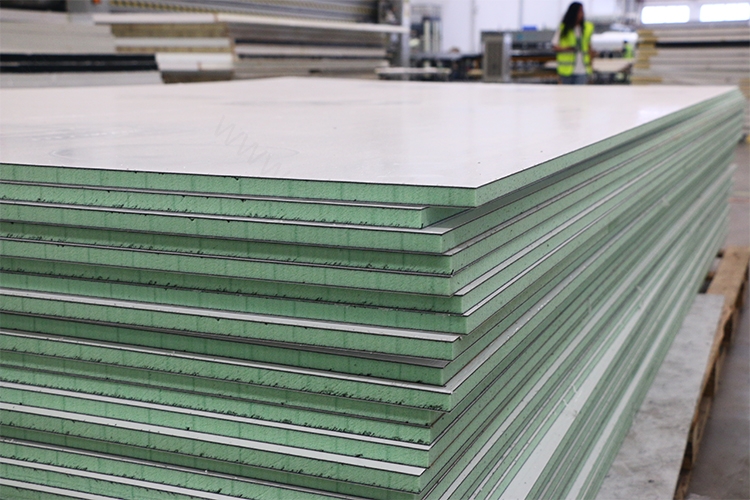

- Width: ≤3.2m

- Length: ≤12m

- Thickness: 10~120mm

- Core Density: 50~300 kg/m³

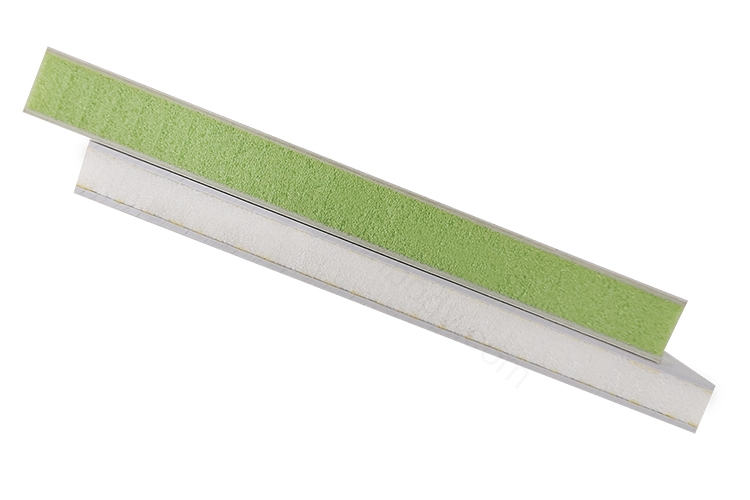

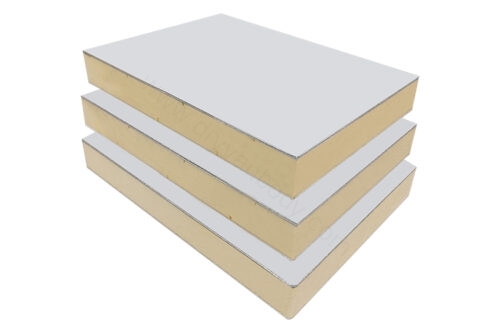

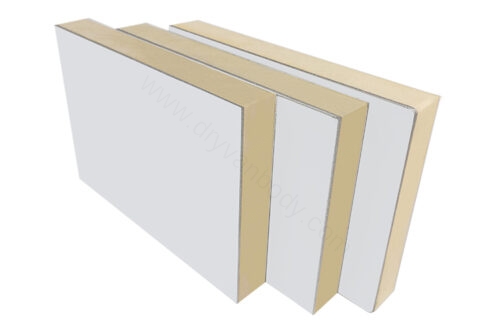

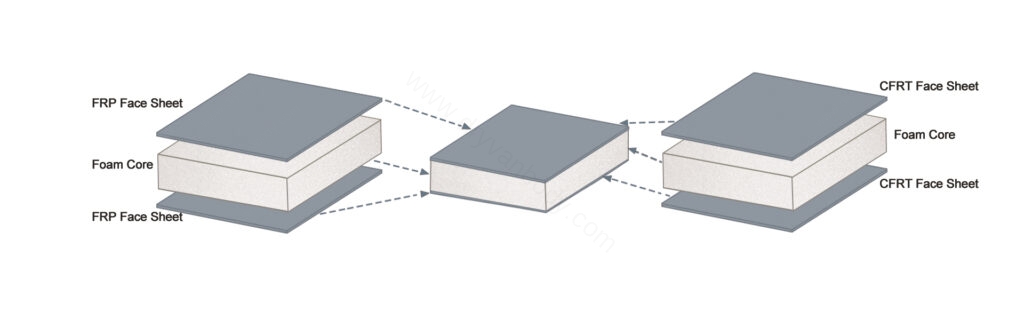

Structure of Truck Body Panel

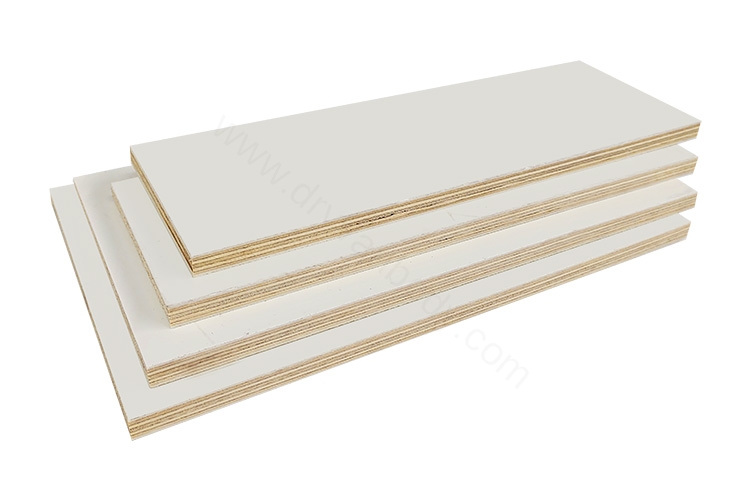

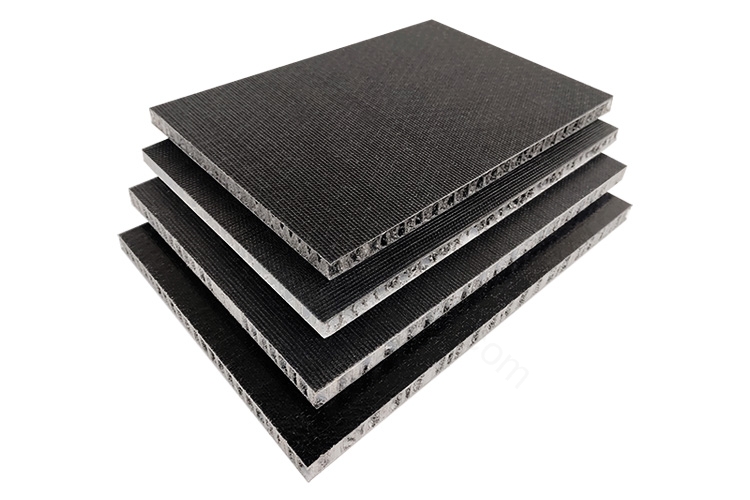

PET foam cores have a wide range of compatibility and can be efficiently laminated with various skin materials such as FRP, aluminium, stainless steel, colour coated steel and plywood.

Features of Truck Body Fiberglass PET Foam Panel

- Lightweight: FRP PET foam panels are lighter than traditional materials.

- High strength: FRP PET foam sandwich panels have good compressive strength and impact strength, which can provide effective body protection.

- Heat insulation: FRP PET foam composite panels have good thermal insulation properties, which can help keep the temperature in the car stable.

- Waterproof: FRP PET foam sandwich panels have good waterproof and moisture resistance, suitable for use in various climate conditions.

- Chemical Resistance: PET foam is highly resistant to a wide range of chemicals and solvents.

- Easy to process: PET foam panels can be easily cut, shaped and installed, and can be customized according to needs.

- Environmental protection: PET foam can be recycled.

- Flat & Smooth surface: Low wind resistance, easy to clean, and convenient for customizing body color, brand logo or advertising.

- Anti-scratch: Continuous glass fiber reinforced plastic is used as the surface layer of the panel, which has anti-scratch performance and extends the service life of the panel.

Fiberglass PET Foam Sandwich Panels

CARBODY has successfully developed CFRT (Continuous Glass Fibre Reinforced Thermoplastic), a material that exhibits significantly higher toughness than conventional thermoset FRP. CFRT not only maintains its high strength properties, but also achieves a lightweight and thin design, which is an important technological innovation in the field of materials science.

Applications

PET foam sandwich panels are widely used in vehicles, construction, transportation, ships, furniture, etc. Glass fiber PET composite panels are lighter, stronger, more durable and less expensive than traditional metal or wood materials, so they are widely used in wall panels, floors, partitions and roof panels in RV and box truck manufacturing.