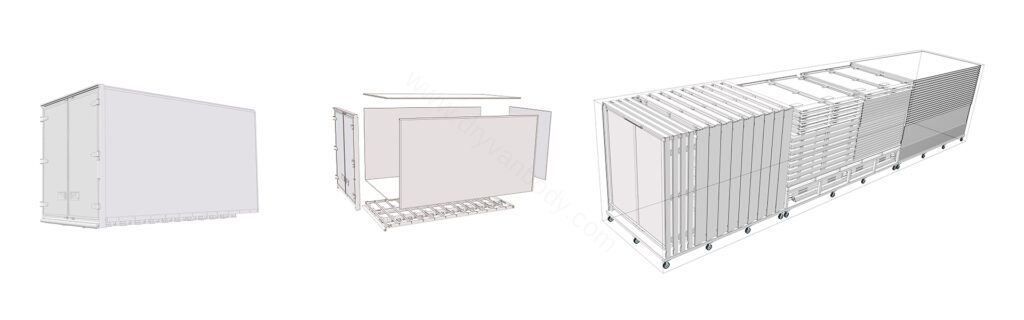

Dry Freight Truck Body CKD Kits refer to the CKD parts of freight truck bodies. These parts are broken down into smaller units for transportation and assembled at the destination. Its characteristics include modular design, convenient and fast assembly process, and flexibility to adapt to different specifications and requirements. This approach makes production and transportation more efficient. Carbody specializes in providing lightweight box truck bodies that can be assembled quickly. Its modular design allows for assembly in a short period.

Descrição

Dry Freight Truck Body CKD Kits refer to the CKD parts of dry truck bodies. These parts are broken down into smaller units for transportation and assembled at the destination. The kit’s characteristics include a modular design, a convenient and fast assembly process, and the flexibility to adapt to different specifications and requirements. This approach makes production and transportation more efficient.

Carbody specializes in providing lightweight box truck bodies that can be assembled quickly. Its modular design allows for assembly in a short time.

Materiais

- Painéis compósitos de contraplacado de fibra de vidro.

- Painéis compósitos de espuma PET de fibra de vidro.

- Painéis compósitos alveolares em fibra de vidro e polipropileno.

Características

- Leve.

- Duradouro.

- À prova de água.

- Acessível.

Os nossos serviços personalizados

- Fornecer soluções de conceção e fabrico de acordo com os requisitos da aplicação

- Desenvolver novos materiais e novas tecnologias para proporcionar mais benefícios económicos aos utilizadores.

- As carroçarias de camiões de caixa fechada são entregues ao comprador sob a forma de CKD ou SKD.

As a pioneer in the field of truck lightweight, CARBODY continues to work at the forefront of research and development of new materials and processes, and is committed to creating safe, efficient, economical and environmentally friendly design and manufacturing solutions for truck manufacturers and dealers around the world. We focus on ensuring transport safety and structural strength while minimizing body weight through innovative technologies, thereby significantly improving transport efficiency and optimizing operating costs, helping customers to achieve win-win results in terms of economic efficiency and environmental protection.

Vasta gama de cenários de aplicação

CARBODY specializes in tailor-made, efficient dry truck body solutions for a wide range of industries. We work with a wide range of non-liquid and non-refrigerated cargoes to ensure optimum loading efficiency and safety for every transport. Whether it’s everyday consumer goods, construction materials, or industrial equipment, CARBODY provides professional, reliable and cargo-specific body designs to help our customers excel in logistics.

- Fabrico: Transporte de matérias-primas, produtos semi-acabados e produtos acabados.

- Alimentação e bebidas: Adequado para alimentos secos que não requerem refrigeração, tais como alimentos enlatados, cereais, snacks, etc.

- Produtos de papel e impressão: Transporte de papel, impressão, materiais de embalagem, etc.

- Mobiliário e bens de uso doméstico: Transporte de mobiliário, decorações para a casa, artigos de cozinha, etc.

- Peças para automóveis: Transporte de peças e acessórios para automóveis.

- Comércio eletrónico: Entrega de encomendas de compras em linha.

- Equipamentos e materiais industriais: Transporte de equipamentos industriais, ferramentas, materiais de construção, etc.

- Artigos de papelaria e material de escritório: Transporte de material de escritório, material escolar, artigos de papelaria, etc.

- Retalho: Transporte de diversos bens de primeira necessidade, vestuário, produtos electrónicos, etc.

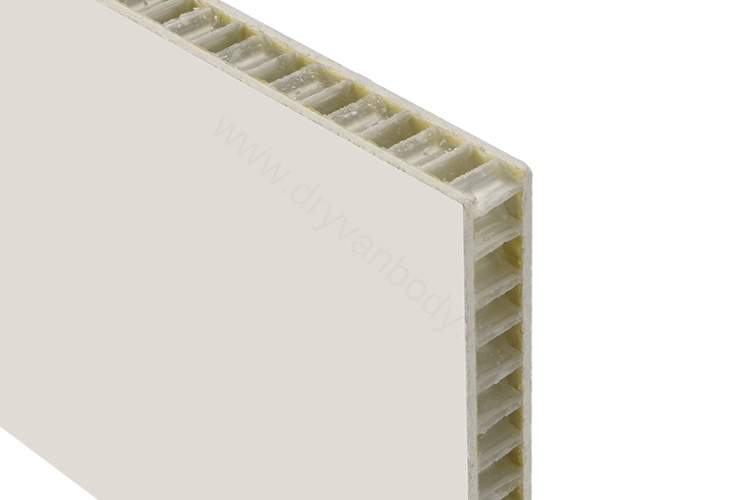

Materiais leves e ecológicos

O peso da carroçaria do camião é reduzido através da utilização de materiais de alta resistência e baixa densidade, assegurando simultaneamente a resistência estrutural e a durabilidade. Desenvolvemos novos materiais compósitos de elevada resistência para substituir os metais e a madeira tradicionais, o que reduz significativamente o peso da carroçaria e os custos operacionais. A maioria destes novos materiais compósitos é reciclável, o que promove o desenvolvimento de uma economia sustentável.

Painéis compostos de espuma PET FRP

PET is a recyclable closed-cell foam and is a highly utilized foam material in a sustainable economy. Fibreglass PET foam composite panels are lightweight, waterproof, structurally stable and resistant to deformation.

- Pele: Chapas FRP, chapas CFRT (termoplástico reforçado com fibras contínuas).

- Núcleo: Espuma de PET (politereftalato de etileno).

Painéis compósitos de contraplacado FRP

O contraplacado é o material económico preferido para o fabrico de camiões secos devido à sua elevada resistência e baixo custo.

- Pele: Chapas FRP, chapas CFRT (termoplástico reforçado com fibras contínuas).

- Núcleo: Contraplacado

Painéis compósitos alveolares de polipropileno FRP

Polypropylene honeycomb panel is a lightweight and high-strength structural material whose unique honeycomb geometric design gives it excellent mechanical properties. The polypropylene honeycomb sandwich panel with fiberglass facing not only significantly improves its strength, but also maintains extremely lightweight and excellent deformation resistance.

- Pele: Chapas FRP, chapas CFRT (termoplástico reforçado com fibras contínuas).

- Núcleo: Polipropileno (PP).

Montagem rápida e fácil

- Menos operadores.

- Ferramentas de instalação simples.

- Instalação rápida.

- Pode ser realizado por operadores não profissionais.

- Pegada pequena.

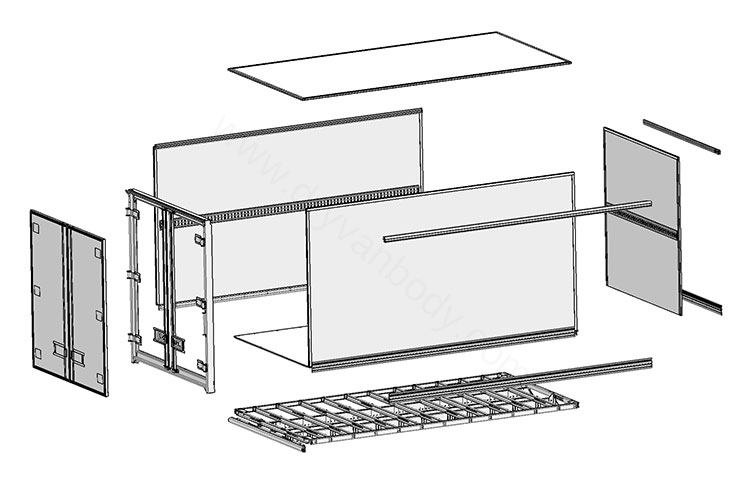

Our box truck bodies offer flexible transport options, with the option of delivering to the destination in either completely knocked down (CKD) or semi-knocked down (SKD) form. All components are meticulously manufactured in our highly specialized factories and undergo a stringent quality inspection process to ensure that every part meets the highest standards of quality.

Once the kit arrives safely at its destination, it is accompanied by a detailed and easy-to-understand installation guide, which allows the operator to get up to speed and start assembling the unit with ease. As we have already pre-assembled the main components, the remaining parts can be efficiently assembled by the purchaser’s technical team or by workers with only basic skills, using common hand tools such as drills, spanners, hammers, and lifting equipment. This design greatly reduces the technical threshold for installation and can be performed by non-professionals with guidance.

Typically, a body can be assembled by two to three people, which not only improves work efficiency, but also effectively saves labor costs. We are committed to providing convenient and efficient total solutions to ensure that our customers can enjoy a worry-free service experience from transport to installation.

Tamanho comum

A CARBODY fornece personalização de carroçarias para camiões de carga seca com um comprimento máximo de 12m. (Personalizar diferentes tamanhos e especificações de acordo com os requisitos). Os tamanhos mais comuns são os seguintes:

| Tipo | Comprimento | Largura | Altura |

| Serviço pequeno | 3m a 6m | 1,8 m a 2,1 m | 1,8 m a 2,2 m |

| Serviço médio | 6m a 9m | 2,2 m a 2,5 m | 2,2 m a 2,5 m |

| Serviço grande | 9m a 12m | 2,4 m a 2,6 m | 2,5m a 3m |

Tipos de furgões secos

Oferecemos soluções de design individual para algumas carroçarias de camiões para aplicações especiais.

Camiões fechados

Camiões para portas de enrolar

Camiões de asa

Trailers

Carroceria de caminhão de carga personalizada CKD

We specialize in the careful design and manufacture of a comprehensive range of body components based on the specific needs of our customers. These components include, but are not limited to: rear doors, side doors, precision corner covers, body edge profiles, advanced door locking systems, durable floor assemblies, E-rails, highly efficient suspension systems, reinforced sub-frames, safety-compliant light assemblies, crash bumpers, protective side guards, and convenient rear door lifting platforms. We are committed to providing high-quality, customized solutions to ensure that each component is perfectly integrated into the overall design of the vehicle, enhancing its performance, safety and aesthetics.

Força da empresa

- Colaboração com clientes em mais de 50 países e regiões.

- 20 anos de experiência na conceção e desenvolvimento de camiões quantitativos.

- More than 100 manufacturing teams.

- Mais de 10 equipas de serviços linguísticos internacionais (inglês, russo, francês, espanhol, português, árabe, alemão, italiano, japonês, coreano).

Embalagem e expedição

To ensure that the truck body CKD kits can reach their destinations safely and without any damage, and to facilitate buyers’ unloading operations easily and quickly, we have tailor-made highly reliable packaging solutions for each batch of goods. These packages cannot only effectively isolate them from harsh environmental factors such as seawater, rain, snow and ice, but also have excellent shock, collision and compression resistance to cope with the challenges of bumps, collisions and crushing that may be encountered during long-distance transport. This all-round protection design ensures that the kit is still in perfect condition when it arrives at the customer’s hands, laying a solid foundation for the subsequent assembly work.