Luton truck bodies are a common body type for light commercial trucks and are commonly used in the retail, furniture moving and logistics industries.

Our Customized Services

- Box design.

- Optimized box composite panels.

- Customized metal accessories.

- Assembled box.

Description

A Luton truck body is a cargo box mounted on a truck chassis. They are mainly used in light trucks and are widely used for short-distance and urban transportation.Our Truck Body Features

- Modular Design (CKD/SKD).

- Lightweight Material.

- Flexible Configuration.

- Durable.

- Eco-friendly.

- Affordable Price.

- Easy Maintenance.

Eco-Friendly Materials

- External layer: FRP (Glass Fiber Reinforced Thermoset Plastic); CFRT (Continuous Fiber Reinforced Thermoplastic).

- Core: PET (Polyethylene Terephthalate) foam. (Density: 60-300kg/m³); PP (Polypropylene ) Honeycomb. (Density: 80-120kg/m³) Plywood. (Birch, pine, poplar, eucalyptus, oak, etc.)

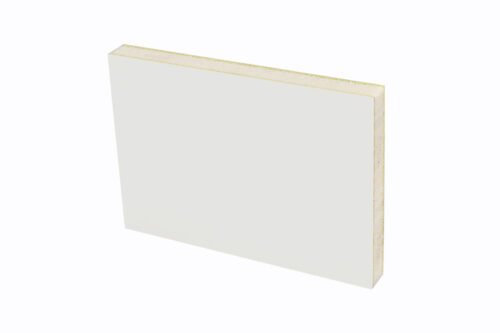

XPS Foam FRP Sandwich Panel

- Benefits: XPS foam has low water absorption, excellent thermal insulation performance, and a certain hardness.

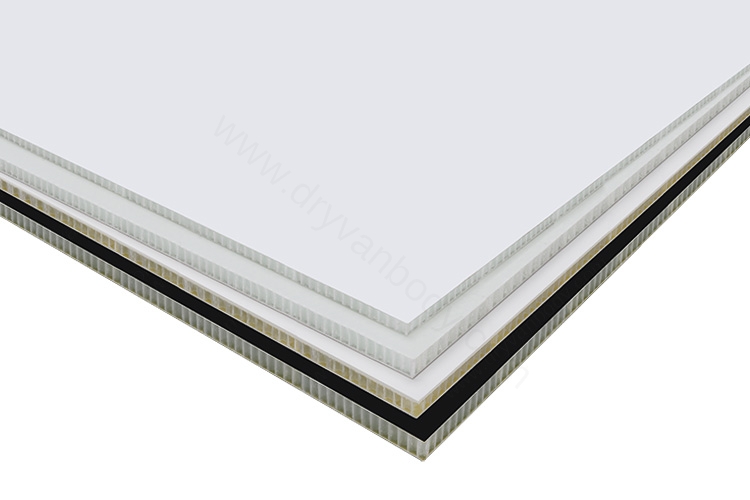

Polypropylene Honeycomb FRP Sandwich Panels

- Benefits: The PP honeycomb panel is a thermoplastic polypropylene plastic with a high strength-to-weight ratio and is a representative lightweight material.

PET Foam FRP Sandwich Panel

- Benefits: Closed-cell PET foam is lightweight and highly rigid. This material is recyclable and eco-friendly.

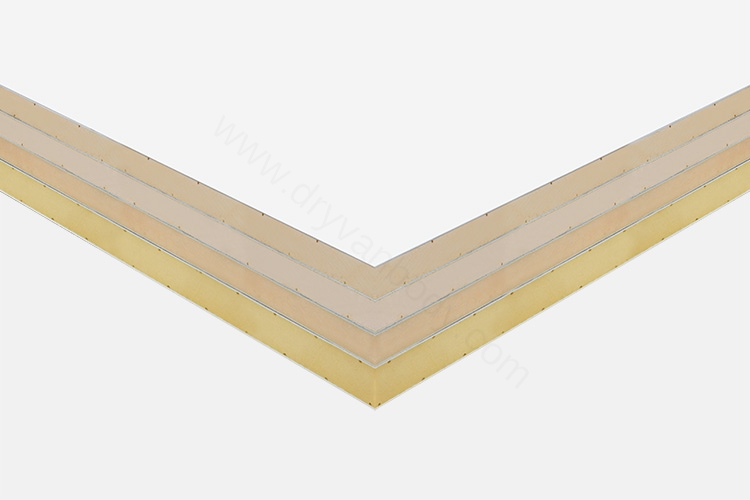

Plywood FRP Sandwich Panel

- Benefits: Plywood is made of multiple layers of veneer under high temperature and pressure, and has extremely high strength. It is an economical choice.

Engineer Team

We have a professional Luton truck body design team with more than 20 years of experience, providing customers with professional design and optimization solutions. When designing a Luton truck body, our team will consider the following factors:- Total vehicle weight.

- Load capacity.

- Material rigidity.

- Fatigue strength.

- Aerodynamics.

Truck Options

- Corner caps, etc.

- Cargo-Track Systems.

- Tie-Down Straps and Ratchets.

- Cargo Bars.

- Roll-Up Doors.

- Lighting Kits.

- Flooring Options.

- Security Locks.

- Backup Cameras

- Subframes.

- Edge profiles.

- Door frames.

- Hinges.

Our Company Strength

Truck Composite Panel Production Line

CARBODY has both adhesive composite panel and thermoplastic composite panel process technology, has multiple first-class truck composite panel production lines, and implements strict quality standards. We use the latest manufacturing processes, such as automated welding, high-precision CNC cutting, and other technologies, to significantly improve production efficiency and product quality. The daily production area of composite panels reaches thousands of square meters, and the annual output can meet the manufacturing needs of tens of thousands of box truck bodies.

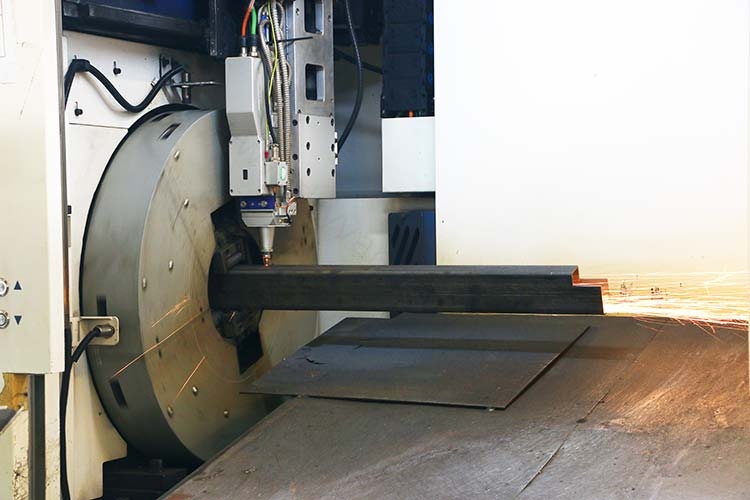

Metal Parts Processing Center

We offer a range of components including truck floors, door frames, edging profiles, kick plates, bumpers, hinges, door locks, handles, etc. We have several machining centers for sheet metal processing, laser welding, laser cutting, milling, aluminum extrusion profiles, etc.