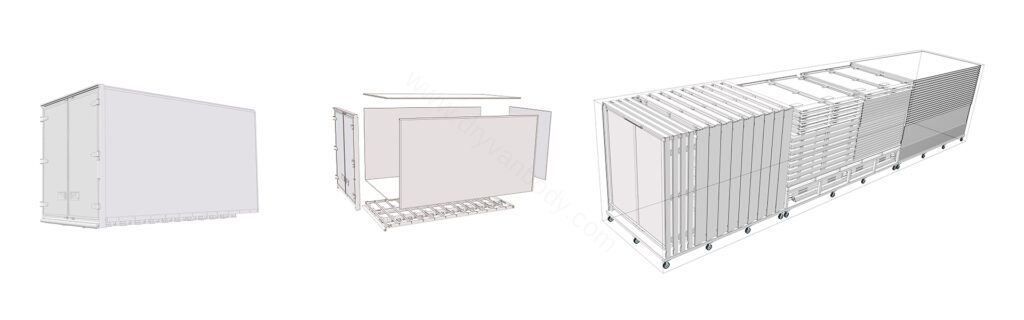

CARBODY is a custom dry van body manufacturer that offers quick-assembly lightweight box CKD (Completely Knocked Down) kits. Its modular design makes the assembly process quick and easy.

Box Advantages

- New technology, new solution, impact resistance

- No volatility, no odor

- Anti-corrosion, mildew-proof, waterproof

- Lightweight, high strength

Description

CARBODY (Shanghai CARBODY Automobile Technology Co., Ltd.), as a customized dry truck body manufacturer, focuses on providing lightweight, modular, platform-based body design solutions for logistics, transportation and other industries. Dedicated to the research and design of lightweight vehicle bodies and the application of new materials, the company has one-stop design and development capabilities for the entire vehicle, from product planning, creative design and engineering design to prototype and exhibition vehicle production.

Materials

- Fiberglass plywood composite panels.

- Fiberglass PET foam composite panels.

- Fiberglass polypropylene honeycomb composite panels.

Features

- Lightweight.

- Durable.

- Waterproof.

- Affordable.

Custom Dry Van Body Services

- Provide design and manufacturing solutions according to application requirements

- Develop new materials and new technologies to bring more economic benefits to users.

- Box truck bodies are delivered to the purchaser in the form of CKD or SKD.

Wide Range of Application Scenarios

CARBODY is a leading custom dry van body manufacturer, providing high-quality dry van truck body solutions that meet international standards. Whether it is daily consumer goods, construction materials or industrial equipment, CARBODY can provide professional, reliable, and cargo-specific body design to help our customers excel in logistics.

- Manufacturing: Transportation of raw materials, semi-finished products and finished products.

- Retail: Transportation of various daily necessities, clothing, electronic products, etc.

- Food and Beverage: Suitable for dry food that does not require refrigeration, such as canned food, grains, snacks, etc.

- Paper Products and Printing: Transportation of paper, printing, packaging materials, etc.

- Furniture and Household Goods: Transportation of furniture, home decorations, kitchen supplies, etc.

- Auto Parts: Transportation of auto parts and accessories.

- E-commerce: Delivery of online shopping orders.

- Industrial Equipment and Materials: Transportation of industrial equipment, tools, construction materials, etc.

- Stationery and Office Supplies: Transportation of office supplies, school supplies, stationery, etc.

Lightweight & Eco-Friendly Materials

The weight of the truck body is reduced by using high-strength, low-density materials while ensuring structural strength and durability. We have developed new high-strength composite materials to replace traditional metals and wood, which greatly reduces the weight of the body and reduces operating costs. Most of these new composite materials are recyclable, which promotes the development of a sustainable economy.

FRP PET Foam Composite Panels

PET is a recyclable closed-cell foam and is a highly utilized foam material in a sustainable economy. Fibreglass PET foam composite panels are lightweight, waterproof, structurally stable and resistant to deformation.- Skin: FRP sheets, CFRT (continuous fiber reinforced thermoplastic) sheets.

- Core: PET (Polyethylene terephthalate) foam.

FRP Plywood Composite Panels

Plywood is the preferred economical material for manufacturing dry trucks due to its high strength and low cost.- Skin: FRP sheets, CFRT (continuous fiber reinforced thermoplastic) sheets.

- Core: Plywood

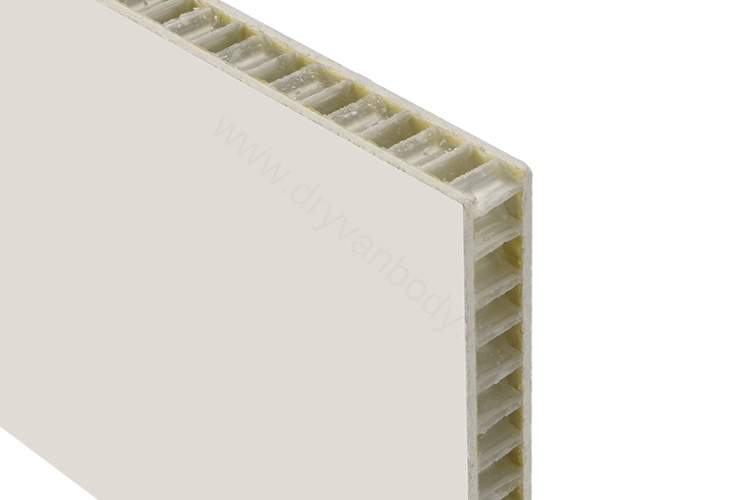

FRP Polypropylene Honeycomb Composite Panels

Polypropylene honeycomb panel is a lightweight and high-strength structural material whose unique honeycomb geometric design gives it excellent mechanical properties. The polypropylene honeycomb sandwich panel with fiberglass facing not only significantly improves its strength, but also maintains extremely light weight and excellent deformation resistance.- Skin: FRP sheets, CFRT (continuous fiber reinforced thermoplastic) sheets.

- Core: Polypropylene (PP).

Quick and Easy Assembly

- Fewer operators.

- Simple installation tools.

- Fast installation.

- Can be completed by non-professional operators.

- Small footprint.

Our box truck bodies offer flexible transport options, with the option of delivering to the destination in either completely knocked down (CKD) or semi-knocked down (SKD) form. All components are meticulously manufactured in our highly specialized factories and undergo a stringent quality inspection process to ensure that every part meets the highest standards of quality.

Once the kit arrives safely at its destination, it is accompanied by a detailed and easy-to-understand installation guide, which allows the operator to get up to speed and start assembling the unit with ease. As we have already pre-assembled the main components, the remaining parts can be efficiently assembled by the purchaser’s technical team or by workers with only basic skills, using common hand tools such as drills, spanners, hammers and lifting equipment. This design greatly reduces the technical threshold for installation and can be performed by non-professionals with guidance.

Typically, a body can be assembled by two to three people, which not only improves work efficiency, but also effectively saves labor costs. We are committed to providing convenient and efficient total solutions to ensure that our customers can enjoy a worry-free service experience from transport to installation.

Common Size

| Type | Length | Width | Height |

| Small Duty | 3m to 6m | 1.8m to 2.1m | 1.8m to 2.2m |

| Medium Duty | 6m to 9m | 2.2m to 2.5m | 2.2m to 2.5m |

| Large Duty | 9m to 12m | 2.4m to 2.6m | 2.5m to 3m |

Dry Van Types

We offer individual design solutions for some truck bodies for special applications.

Closed Trucks

Roll-Up Door Trucks

Wing Trucks

Trailers

Custom Dry Van Body CKD Parts

We specialize in the careful design and manufacture of a comprehensive range of body components based on the specific needs of our customers. These components include, but are not limited to: rear doors, side doors, precision corner covers, body edge profiles, advanced door locking systems, durable floor assemblies, E-rails, highly efficient suspension systems, reinforced sub-frames, safety-compliant light assemblies, crash bumpers, protective side guards, and convenient rear door lifting platforms. We are committed to providing high-quality, customized solutions to ensure that each component is perfectly integrated into the overall design of the vehicle, enhancing its performance, safety and aesthetics.

Company Strength

- Cooperating with customers in more than 50 countries and regions.

- 20 years of experience in quantitative truck design and development.

- More than 100 manufacturing teams.

- More than 10 international language service teams (English, Russian, French, Spanish, Portuguese, Arabic, German, Italian, Japanese, Korean).

Packing and Shipping