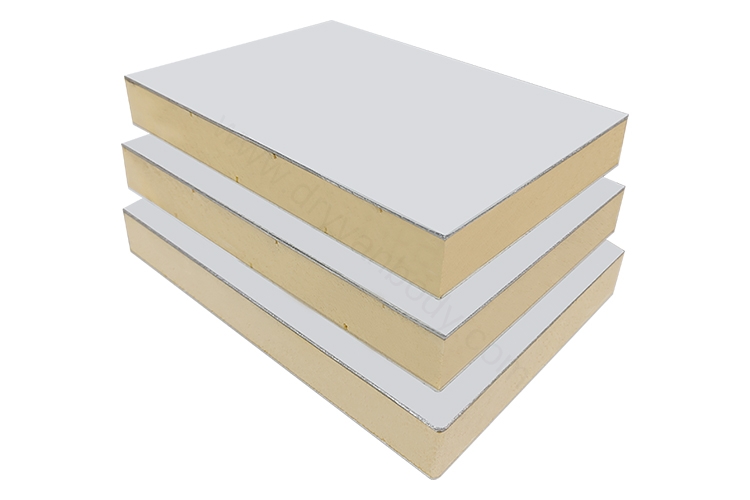

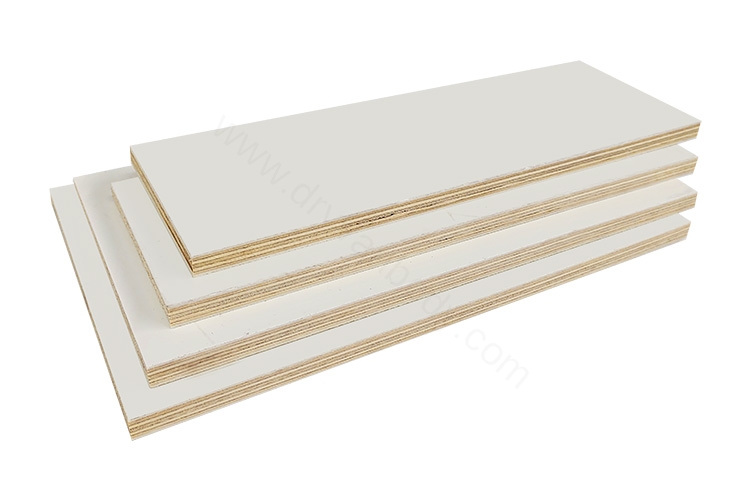

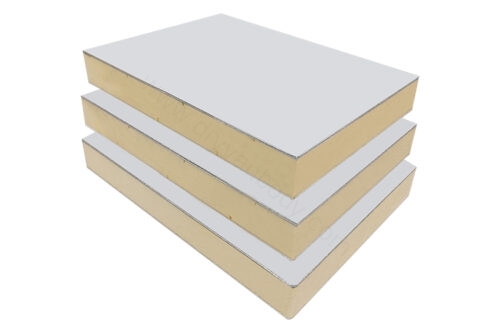

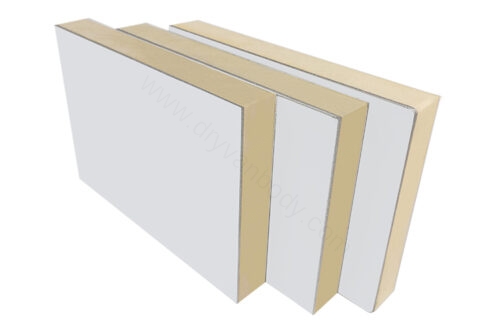

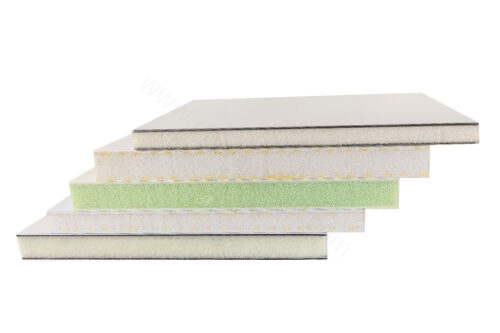

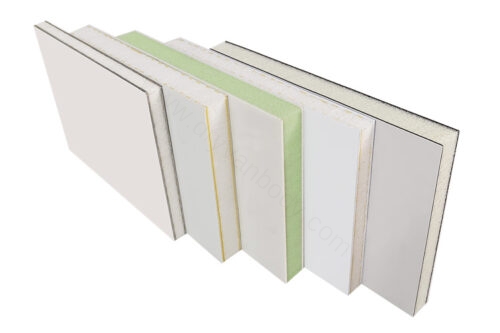

Fiberglass plywood is a composite material panel consisting of FRP skin and plywood (or called sandwich layer). The structure of the FRP skin plywood sandwich panel has the characteristics of durability, easy cutting, and high nail-holding force.

説明

Fiberglass plywood for freight truck bodies is a high-performance composite material designed specifically for dry freight vehicles. It is widely used in the manufacture and modification of truck bodies. FRP has the advantages of lightweight, high strength, and corrosion resistance, which can effectively improve the durability and transportation efficiency of truck bodies.

ガラス繊維合板複合材の構造

FRP plywood is a composite material made from FRP sheets and a plywood core. It can be cut and used like ordinary plywood. It has better durability and waterproof performance.

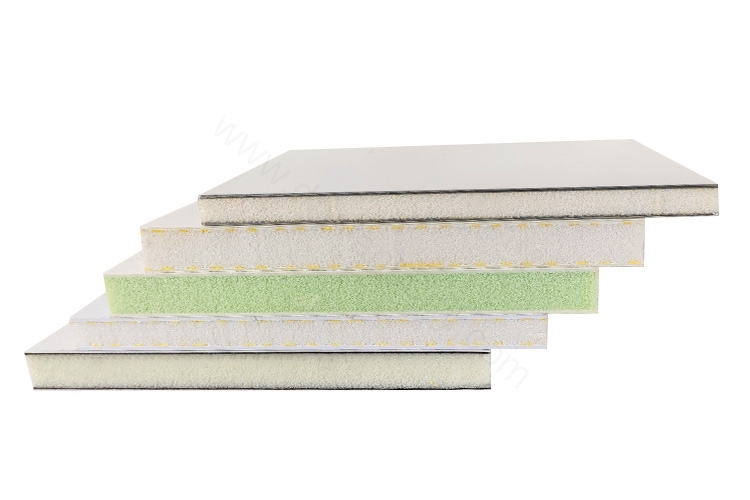

FRP Foam Plywood Panel Specifications

| FRP Thickness | 0.7–5 mm |

| 合板素材 | Poplar, Beech, Birch, Oak, Pine, etc. |

| Maximum Width | 3.2 m |

| Maximum Length | 12 m |

| UV Resistant | Yes |

| Water Resistance | Yes |

| Flame Retardant Grade | B2 |

| 耐用年数 | 20 years |

ガラス繊維合板の利点

- 強度が高い:FRP表皮は強度と剛性が高く、大きな荷重や衝撃に耐えることができる。

- Weather resistance: FRP has strong self-cleaning, UV resistance, anti-static and corrosion resistance.

- 軽量:金属材料と比較して、FRP表皮合板サンドイッチパネルは軽量であり、構造全体の軽量化に寄与する。

- 断熱性:グラスファイバー合板は超低温でも脆くならず、高温でも変形せず、熱の伝わりを効果的に防ぐことができる。

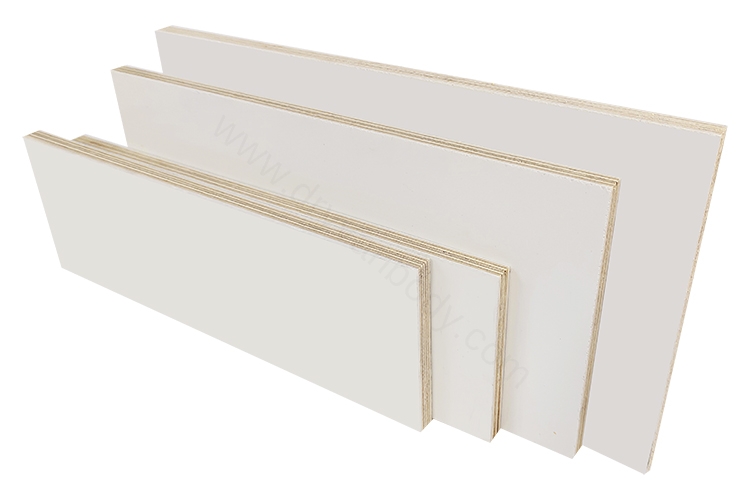

- Easy to process: Both FRP skin and sandwich materials offer excellent processing performance, allowing for cutting, drilling, and other necessary modifications.

Our Advantages

We are a leading fiberglass reinforced plywood manufacturer in China and experts in box truck solutions. Our factory boasts industry-leading production lines for composite panels and offers a range of customized services.

- The sandwich panel undergoes lamination under high pressure in a vacuum environment. The surface of the panel after molding is flat and tightly combined, and the strength is much better than that of ordinary composite panels.

- Customized size: The size of the composite panel can reach 12mx3.2m. {The maximum size of the container is 40 feet (12.03 meters)}

- Processing: High-efficiency and high-precision CNC processing can meet any design requirements.