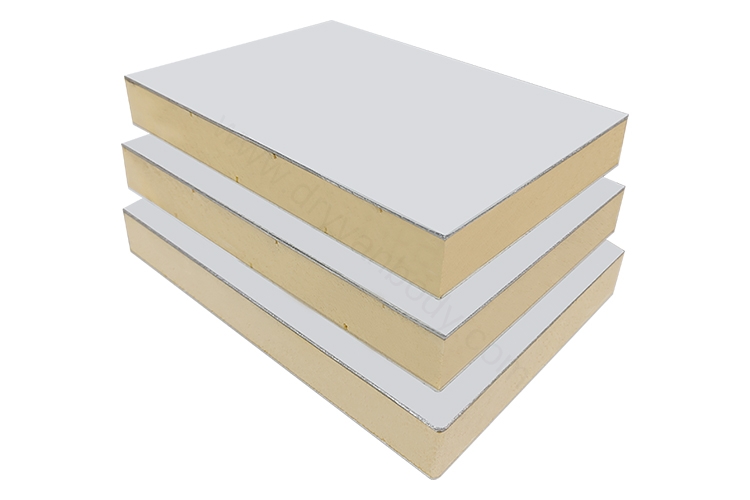

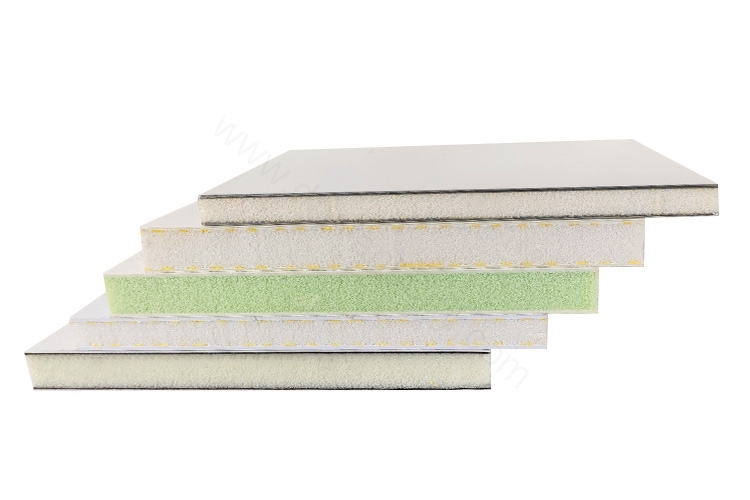

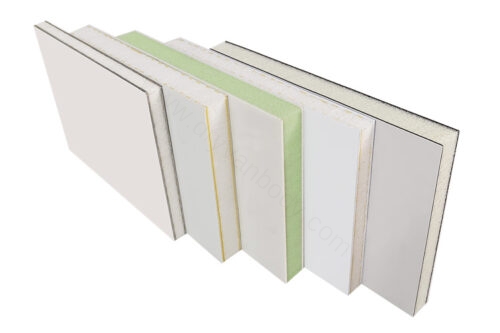

Fiberglass plywood is a composite material panel consisting of FRP skin and plywood (or called sandwich layer). The structure of the FRP skin plywood sandwich panel has the characteristics of durability, easy cutting, and high nail-holding force.

Descrizione

Fiberglass plywood for freight truck bodies is a high-performance composite material designed specifically for dry freight vehicles. It is widely used in the manufacture and modification of truck bodies. FRP has the advantages of lightweight, high strength, and corrosion resistance, which can effectively improve the durability and transportation efficiency of truck bodies.

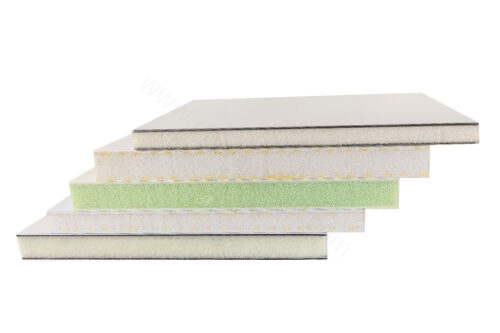

Structure of Fiberglass Plywood Composites

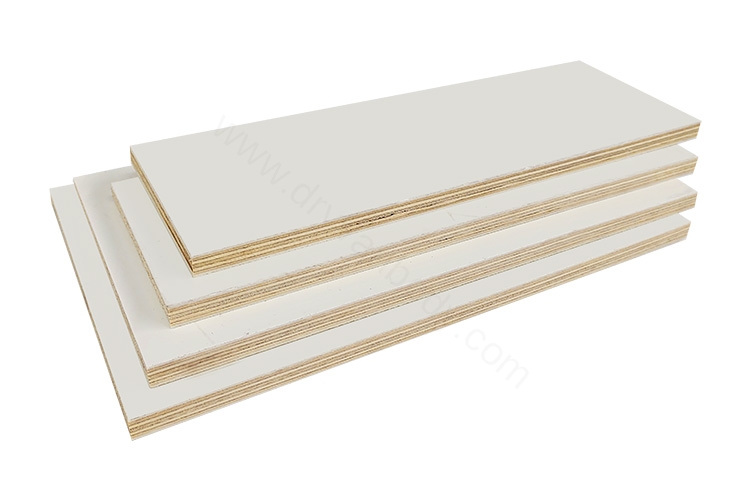

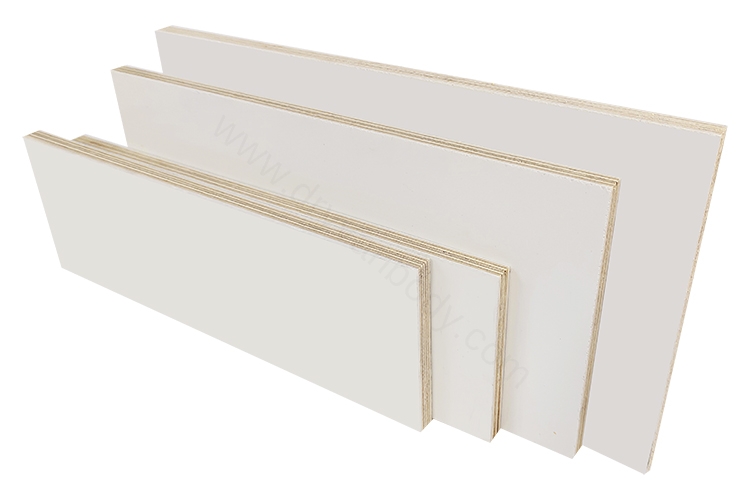

FRP plywood is a composite material made from FRP sheets and a plywood core. It can be cut and used like ordinary plywood. It has better durability and waterproof performance.

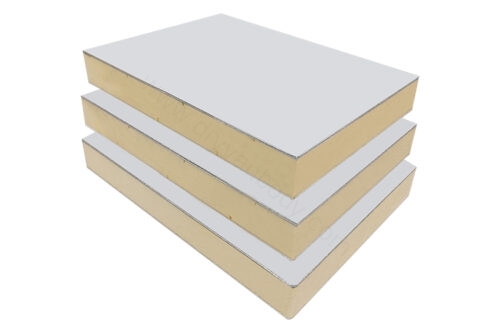

FRP Foam Plywood Panel Specifications

| FRP Thickness | 0.7–5 mm |

| Materiale compensato | Poplar, Beech, Birch, Oak, Pine, etc. |

| Maximum Width | 3.2 m |

| Maximum Length | 12 m |

| UV Resistant | Yes |

| Water Resistance | Yes |

| Flame Retardant Grade | B2 |

| Durata di servizio | 20 years |

Benefits of Fiberglass Plywood

- Alta resistenza: La pelle in FRP ha un'elevata resistenza e rigidità e può sopportare carichi e impatti di grandi dimensioni.

- Weather resistance: FRP has strong self-cleaning, UV resistance, anti-static and corrosion resistance.

- Leggerezza: Rispetto ai materiali metallici, i pannelli sandwich di compensato con rivestimento in FRP hanno un peso inferiore, che favorisce la riduzione del peso della struttura complessiva.

- Heat insulation: Fiberglass plywood will not become brittle at ultra-low temperatures, will not deform at high temperatures, and can effectively prevent heat transfer.

- Easy to process: Both FRP skin and sandwich materials offer excellent processing performance, allowing for cutting, drilling, and other necessary modifications.

Our Advantages

We are a leading fiberglass reinforced plywood manufacturer in China and experts in box truck solutions. Our factory boasts industry-leading production lines for composite panels and offers a range of customized services.

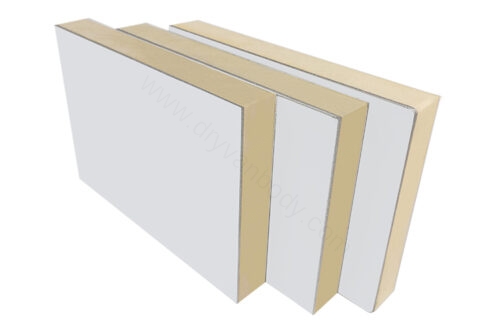

- The sandwich panel undergoes lamination under high pressure in a vacuum environment. The surface of the panel after molding is flat and tightly combined, and the strength is much better than that of ordinary composite panels.

- Customized size: The size of the composite panel can reach 12mx3.2m. {The maximum size of the container is 40 feet (12.03 meters)}

- Processing: High-efficiency and high-precision CNC processing can meet any design requirements.