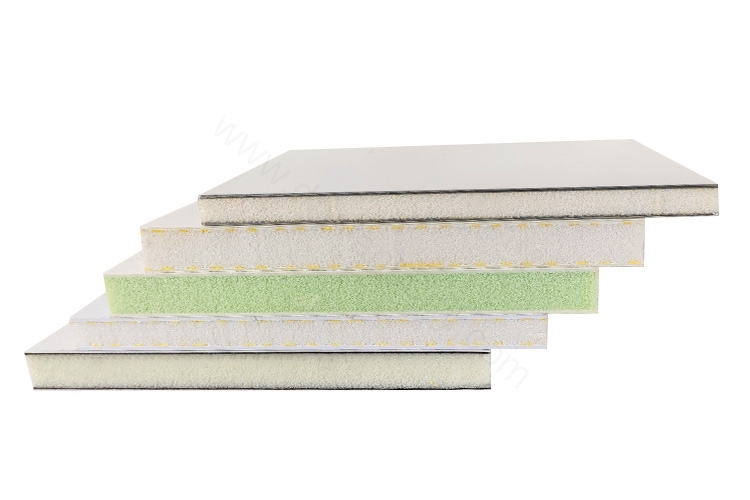

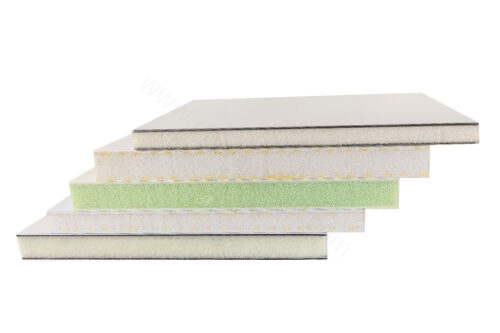

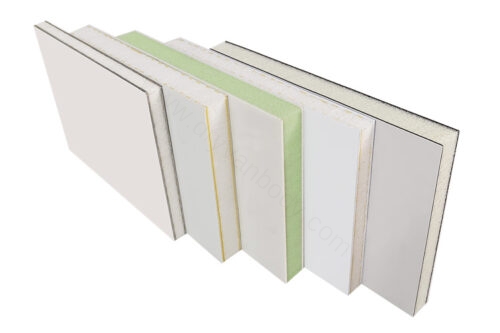

Fiberglass PP honeycomb sandwich panels are high-performance materials widely used in truck body manufacturing. Their sandwich structure includes a glass fiber reinforcement layer and a polypropylene (PP) honeycomb core. The fiberglass layers provide strong tensile strength and impact resistance, while the PP honeycomb core offers extremely low weight and energy absorption capabilities.

Descripción

Fiberglass PP honeycomb sandwich panels are high-performance materials widely used in truck body manufacturing. Their sandwich structure includes a glass fiber reinforcement layer and a polypropylene (PP) honeycomb core. The fiberglass layers provide strong tensile strength and impact resistance, while the PP honeycomb core offers extremely low weight and energy absorption capabilities.

Especificaciones

| Material del núcleo | Polypropylene Honeycomb |

| Skin Material | Thermoset FRP Sheet, Thermoplastic FRP Sheet |

| Longitud | ≤12m |

| Anchura | 50~3200mm |

| Espesor | 9~60mm |

| Density | 60/80/120/160/200kg/m³ |

| Cell Diameter | 6/8/10/12mm |

Features of Fiberglass Honeycomb Panel

- Lightweight: Fiberglass honeycomb panels are lighter than plywood.

- High strength and impact resistance: The honeycomb structure gives the panels higher strength and can withstand greater external impact and pressure.

- Good heat and sound insulation: The core material of fiberglass honeycomb panels usually has good heat and sound insulation properties.

- Corrosion resistance: The fiberglass material itself has strong corrosion resistance and can withstand harsh weather and various chemicals.

- Easy installation: Stable size, easy to cut, easier to install.

- Eco-friendly: Fiberglass honeycomb panel materials are recyclable, meeting the requirements of policies and regulations regarding environmentally friendly materials.

Surface Material

- FRP materials are harder and typically receive a gel coating for improved aesthetics.

- New FRP materials are tougher and more rigid, and can withstand greater external impacts.

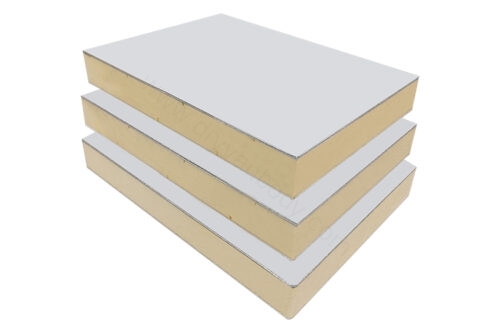

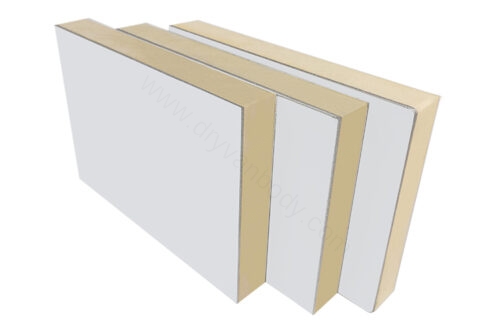

Thermoplastic Fiberglass PP Honeycomb Panel for Truck Bodies

- Hot-melt welding: The new FRP skin and PP honeycomb core are hot-melt welded, eliminating the need for glue and ensuring that no harmful gases are generated during processing.

- Eco-friendly: Thermoplastic honeycomb core and thermoplastic skin are 100% recyclable.

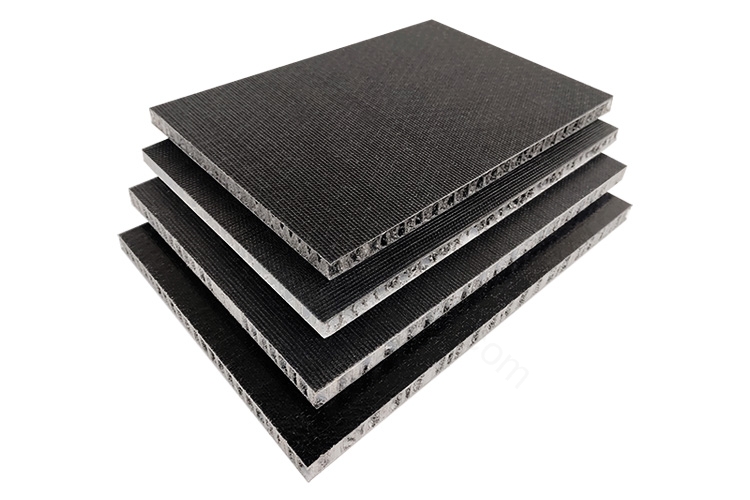

Anti-slip Thermoplastic Honeycomb Panel for Truck Floors

Non-slip thermoplastic fiberglass polypropylene (PP) honeycomb panel is a new type of truck floor material with the advantages of ultra-light, ultra-strong, chemical-resistant, waterproof and moisture-proof.

Its honeycomb structure provides excellent resistance to compression and deformation, while the fiberglass anti-slip surface effectively prevents cargo from sliding and improves transportation safety.