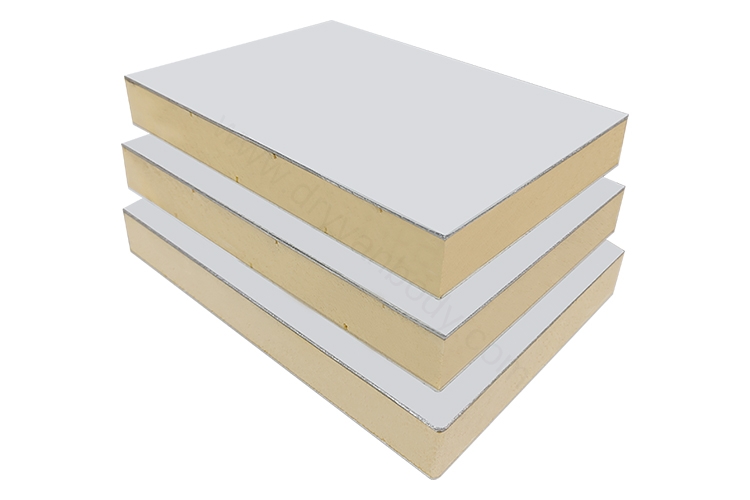

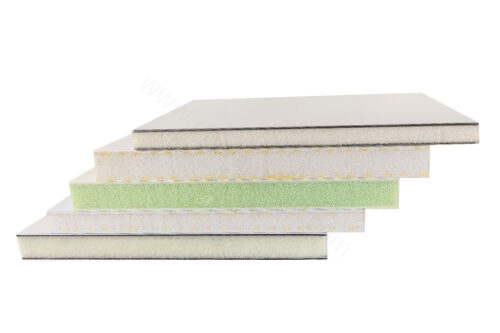

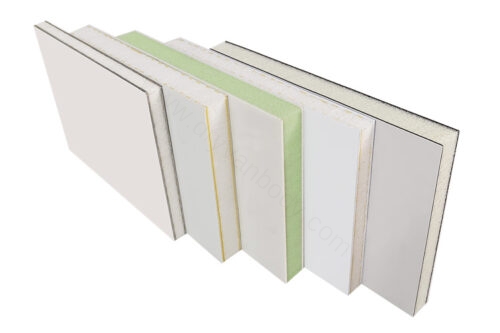

Aluminum XPS foam panel is a sandwich-structure composite material widely used in the manufacture of truck bodies. It consists of an outer aluminum sheet and an inner XPS (extruded polystyrene) foam core, which has excellent strength and thermal insulation properties. This material is not only lightweight and durable, but can also effectively reduce energy consumption during transportation, making it an ideal choice for the modern transportation industry.

الوصف

Aluminum XPS foam panel is a sandwich-structure composite material widely used in the manufacture of truck bodies. It consists of an outer aluminum sheet and an inner XPS (extruded polystyrene) foam core, which has excellent strength and thermal insulation properties. This material is not only lightweight and durable, but can also effectively reduce energy consumption during transportation, making it an ideal choice for the modern transportation industry.

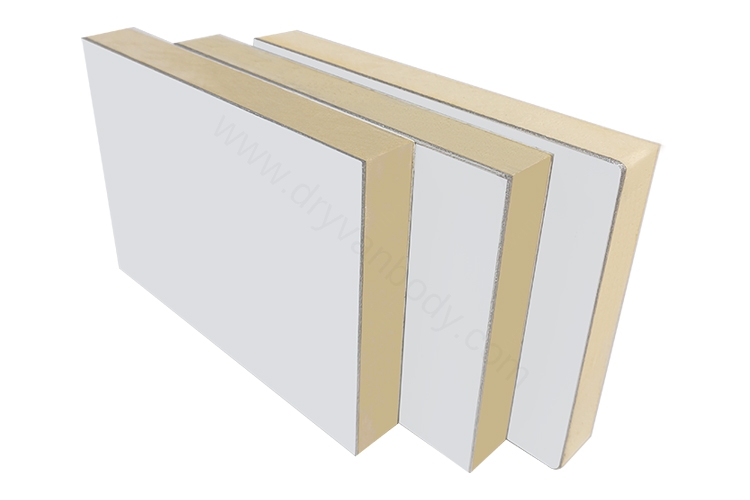

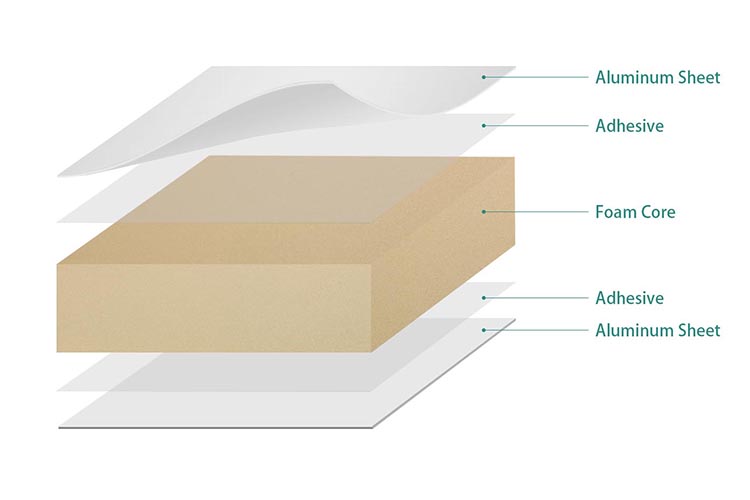

Structure of Aluminum Foam Panel

As the outer layer of the composite panel, aluminum skin usually has good corrosion resistance and mechanical strength, which can effectively protect the internal structure of the vehicle body and resist the erosion of the external environment, such as wind and rain.

This is the core material of the composite panel, which is composed of extruded polystyrene foam (XPS foam). XPS foam has good insulation properties and can effectively isolate the conduction of internal and external temperatures, so that the interior of the vehicle body can maintain a relatively stable temperature in harsh environments.

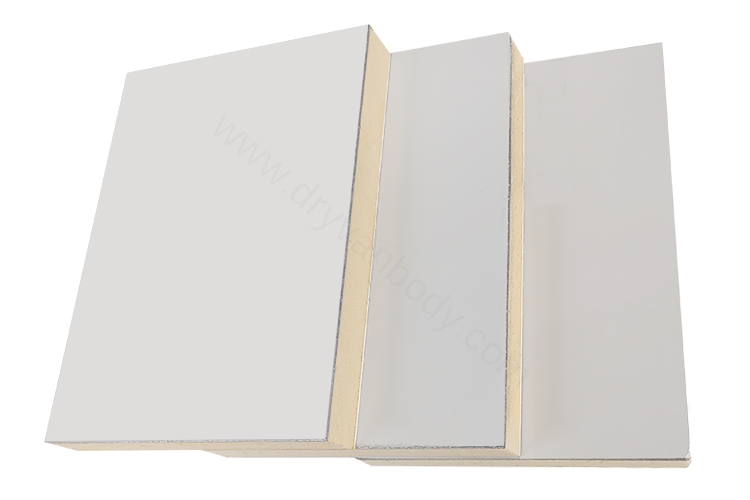

Features of Aluminum Foam Panel

XPS foam core material is light and has a strong structure, which effectively reduces the weight of the entire vehicle body, which is conducive to improving the vehicle’s cargo capacity and fuel efficiency.

XPS foam core has excellent thermal insulation properties, which can effectively reduce the impact of temperature differences inside and outside the vehicle on the cargo, and maintain the quality and safety of the cargo.

The corrosion resistance of aluminum skin and the structural stability of XPS foam make this composite panel have a long service life and can maintain good performance in a variety of harsh environmental conditions.

Compared with traditional materials, aluminum skin XPS foam core composite panels are easy to process and install, which can complete the manufacture of vehicle bodies more quickly and improve production efficiency.

Application

| Application Industry | Dry Truck |

| Standard Thickness | 20~50 mm |

| Finishing Material | 0.48~1.3 mm |

| المادة الأساسية | 20~50 mm |